Latest Version

5.33.0

October 08, 2025

Solaris Oilfield Infrastructure, LLC

Tools

Android

0

Free

com.solaris.lens

Report a Problem

More About Solaris Lens

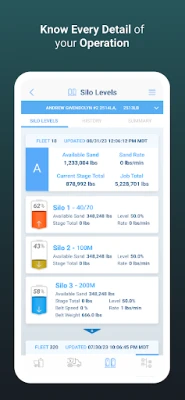

Optimize Your Well Site Monitoring with Advanced Proppant Management Systems

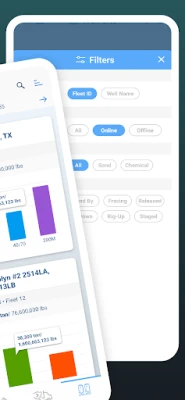

In the ever-evolving landscape of oil and gas extraction, effective well site monitoring is crucial for maximizing efficiency and productivity. Utilizing advanced technologies like Solaris Mobile Proppant Management Systems allows operators to keep a close eye on sand levels and throughput, ensuring optimal performance at every stage of the operation.

Comprehensive Well Site Monitoring

Well site monitoring is essential for maintaining the integrity of operations. With Solaris Mobile Proppant Management Systems, you can effortlessly track sand levels and throughput. This real-time data enables operators to make informed decisions, reducing downtime and enhancing overall productivity.

Benefits of Real-Time Sand Level Tracking

Monitoring sand levels in real-time provides several advantages:

- Enhanced Decision-Making: Access to immediate data allows for quick adjustments to operations, minimizing delays.

- Increased Efficiency: By understanding sand levels, operators can optimize the use of resources, leading to cost savings.

- Improved Safety: Keeping track of sand levels helps prevent overloading and potential hazards at the well site.

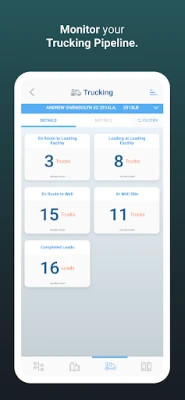

Streamlined Trucking Operations

Efficient trucking operations are vital for the timely delivery of materials to well sites. With advanced tracking capabilities, operators can view comprehensive truck information associated with their well site. This includes:

- Trucks En Route to Loading: Monitor the status of trucks heading to loading facilities, ensuring timely pickups.

- Trucks Loading: Keep track of trucks currently loading materials, allowing for better scheduling and resource allocation.

- Trucks En Route to Well Site: Stay updated on trucks transporting materials to the well site, ensuring a smooth supply chain.

- Trucks at Well Site: Monitor the status of trucks already on-site, facilitating efficient operations and reducing wait times.

Advantages of Real-Time Truck Tracking

Implementing real-time truck tracking offers numerous benefits:

- Improved Logistics: Enhanced visibility into truck movements allows for better planning and coordination.

- Reduced Downtime: By knowing the exact location of trucks, operators can minimize delays and optimize loading times.

- Cost Efficiency: Streamlined trucking operations lead to reduced transportation costs and improved resource management.

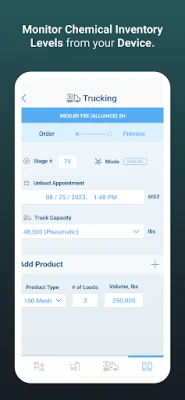

Efficient Management of Loading Facilities

Managing loading facilities effectively is crucial for maintaining a steady supply of materials. With Solaris Mobile Proppant Management Systems, operators can easily view the inventory remaining on purchase orders associated with specific loading facilities. This feature ensures that you are always aware of your stock levels and can plan accordingly.

Key Features of Loading Facility Management

Utilizing advanced management systems for loading facilities provides several key features:

- Inventory Tracking: Keep a close eye on inventory levels, ensuring that you never run out of essential materials.

- Order Management: Streamline the process of managing purchase orders, making it easier to replenish stock as needed.

- Data-Driven Insights: Analyze inventory trends to make informed decisions about future orders and resource allocation.

Conclusion

In conclusion, effective well site monitoring, streamlined trucking operations, and efficient management of loading facilities are essential components of a successful oil and gas operation. By leveraging advanced technologies like Solaris Mobile Proppant Management Systems, operators can enhance productivity, reduce costs, and ensure safety at every stage of the process. Embrace these innovations to stay ahead in the competitive landscape of the industry.

Rate the App

User Reviews

Popular Apps

Editor's Choice