Latest Version

0.0.8

December 12, 2024

Techno-Line LTD

Tools

Android

0

Free

com.technoline.viapp

Report a Problem

More About BWC ViApp

Comprehensive Guide to Boiler Monitoring System Features and Requirements

In today's technologically advanced world, efficient management of heating systems is crucial for both residential and commercial properties. A sophisticated boiler monitoring system offers a range of functionalities that enhance operational efficiency and ensure optimal performance. This article delves into the key features of such systems, their compatibility requirements, and the benefits they provide.

Key Features of Boiler Monitoring Systems

Boiler monitoring systems are designed to provide real-time insights and control over heating installations. Here are the primary functions that these systems offer:

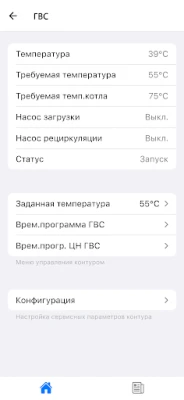

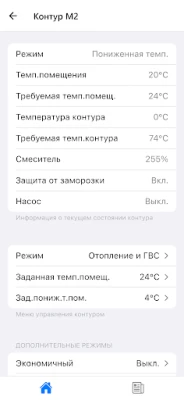

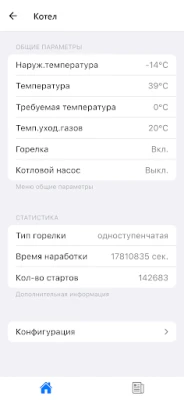

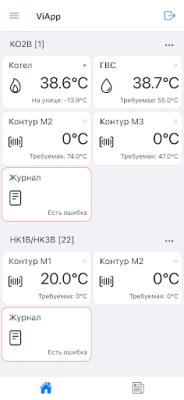

- Real-Time Display of Boiler Parameters: Users can view current operational parameters of the boiler installation, ensuring that everything is functioning within the desired specifications.

- Monitoring Heating Circuit Parameters: The system displays the current parameters of heating circuits, allowing for immediate adjustments if necessary.

- Control Over Heating Circuits: Users can manage various aspects of the heating circuits, including mode settings, temperature adjustments, and scheduling for optimal energy efficiency.

- System Settings Modification: The ability to change system settings for both the boiler and heating circuits ensures that users can tailor operations to their specific needs.

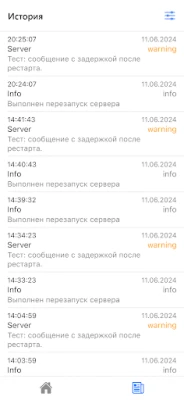

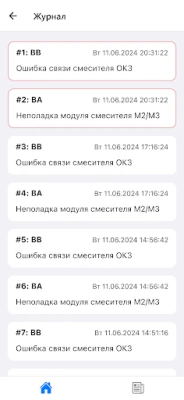

- Error Logging: The system maintains a log of any malfunctions or errors, providing users with a comprehensive overview of operational issues.

- Push and Email Notifications: Users receive immediate alerts via push notifications or emails regarding any errors or system malfunctions, allowing for prompt action.

- Graphical Representation of Historical Data: The system can display archived data in graphical formats, making it easier to analyze trends and performance over time.

- Operational Log: A detailed log of system operations, including parameter changes and errors, helps in troubleshooting and maintenance.

- Access Control Levels: The system provides separate access levels for users and service personnel, ensuring that sensitive information is protected while still allowing for necessary oversight.

Components of the Monitoring System

The boiler monitoring system comprises a data collection system and a mobile application. The data collection server connects to the Vitotronic control system via a digital data bus through an optical connector. Telemetry data is then transmitted to the mobile application, allowing users to monitor their systems remotely.

System Requirements for Optimal Performance

To ensure seamless operation of the boiler monitoring system, the following components are essential:

- Viessmann Vitotronic: This control system is the backbone of the monitoring setup.

- ViServer: The data collection server that facilitates communication between the boiler and the mobile application.

- LAN/WLAN Router: A reliable router is necessary for stable internet connectivity, enabling remote access to the monitoring system.

Compatibility with Controllers

For the monitoring system to function effectively, it must be compatible with specific controllers. The following models are supported:

- Vitodens 200 with Vitotronic 100: Types HC1A/HC1B

- Vitodens 200 with Vitotronic 200: Types HO1A/HO1B

- Vitotronic 100: Types KC2B/KC4B

- Vitotronic 200: Types KO1B/KO2B

- Vitotronic 200: Types HK1B/HK3B

- Vitotronic 300: Types MW1B/MW2B

Conclusion

Implementing a boiler monitoring system not only enhances the efficiency of heating installations but also provides users with the tools necessary for effective management and troubleshooting. With real-time data, error notifications, and detailed logs, users can ensure their systems operate smoothly and efficiently. For more detailed information about the capabilities of our monitoring system, please visit our website: www.techno-line.info.

Rate the App

User Reviews

Popular Apps

Editor's Choice