Latest Version

15

September 03, 2025

Pick6

Games

Android

0

Free

com.Pick6.IdleCandyShop

Report a Problem

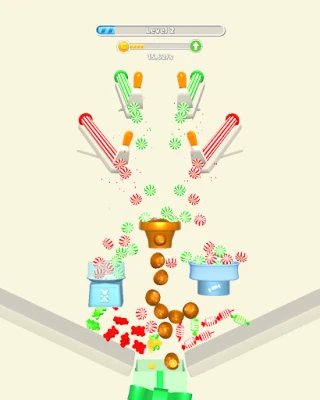

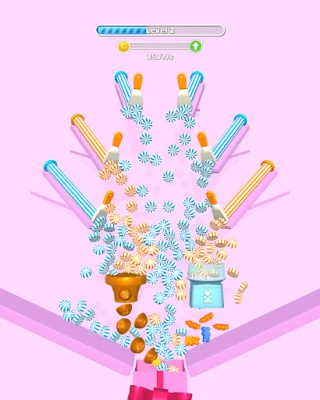

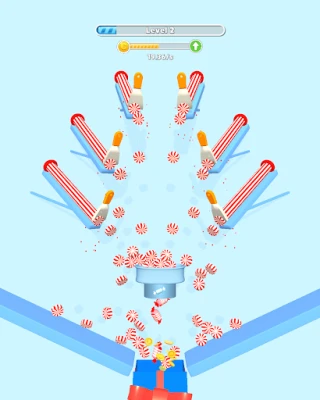

More About Idle Candy Shop

Optimize Your Production Line for Maximum Efficiency

In today's competitive market, managing your production line effectively is crucial for boosting productivity and ensuring operational success. By implementing strategic practices and leveraging modern technologies, you can significantly enhance your production capabilities. This article explores key strategies to optimize your production line and increase overall output.

Understanding Production Line Management

Production line management involves overseeing the entire manufacturing process, from raw material acquisition to the final product delivery. Effective management ensures that each stage of production operates smoothly, minimizing downtime and maximizing efficiency. By focusing on the following areas, you can streamline your operations:

1. Analyze Your Current Workflow

Before making any changes, it’s essential to assess your existing workflow. Identify bottlenecks and inefficiencies that hinder productivity. Utilize data analytics tools to gather insights on production rates, machine performance, and employee output. This analysis will provide a clear picture of where improvements are needed.

2. Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. By adopting lean principles, you can streamline processes, reduce costs, and improve product quality. Key strategies include:

- Value Stream Mapping: Visualize the flow of materials and information to identify waste and areas for improvement.

- Just-In-Time Production: Produce only what is needed, when it is needed, to reduce inventory costs.

- Continuous Improvement: Foster a culture of ongoing enhancement by encouraging employee feedback and suggestions.

3. Invest in Technology and Automation

Incorporating advanced technology and automation into your production line can lead to significant efficiency gains. Consider the following options:

- Robotics: Automate repetitive tasks to reduce labor costs and increase precision.

- IoT Devices: Utilize Internet of Things (IoT) technology to monitor equipment performance in real-time, allowing for proactive maintenance.

- Manufacturing Software: Implement software solutions for inventory management, scheduling, and quality control to streamline operations.

4. Train and Empower Your Workforce

Your employees are your most valuable asset. Providing them with the necessary training and resources can lead to improved productivity. Focus on:

- Skill Development: Offer training programs to enhance employees' skills and knowledge about new technologies and processes.

- Empowerment: Encourage employees to take ownership of their roles and contribute ideas for process improvements.

- Team Collaboration: Foster a collaborative environment where teams can work together to solve problems and innovate.

5. Monitor Performance Metrics

Establishing key performance indicators (KPIs) is essential for tracking the success of your production line optimization efforts. Common KPIs include:

- Overall Equipment Effectiveness (OEE): Measure the efficiency of your equipment by considering availability, performance, and quality.

- Production Cycle Time: Track the time it takes to complete a production cycle to identify areas for improvement.

- Defect Rates: Monitor the quality of your products to ensure they meet customer expectations.

6. Foster a Culture of Safety

Ensuring a safe working environment is vital for maintaining productivity. A culture of safety not only protects employees but also reduces downtime caused by accidents. Implement safety protocols, conduct regular training, and encourage employees to report hazards.

7. Evaluate and Adjust Regularly

Production line optimization is an ongoing process. Regularly evaluate your strategies and make adjustments as needed. Stay informed about industry trends and technological advancements to remain competitive. By continuously refining your processes, you can sustain high levels of productivity and efficiency.

Conclusion

Managing your production line effectively is essential for increasing output and maintaining a competitive edge. By analyzing your workflow, implementing lean principles, investing in technology, training your workforce, monitoring performance metrics, fostering a culture of safety, and regularly evaluating your processes, you can optimize your production line for maximum efficiency. Embrace these strategies to enhance your operations and drive your business toward success.

Rate the App

User Reviews

Popular Apps

Editor's Choice