Latest Version

1.0

August 05, 2025

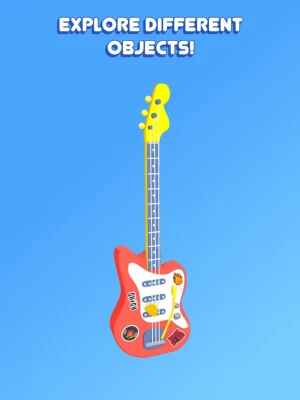

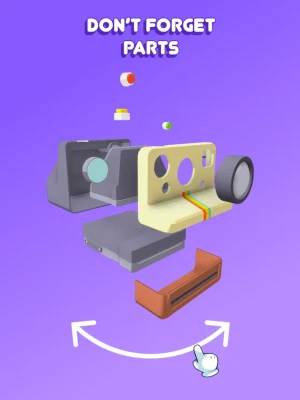

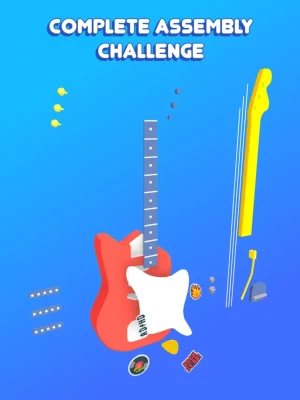

Coolest Assembly Puzzle!

Games

iOS

79.9 MB

0

Free

Report a Problem

More About Assemble Parts

Mastering the Art of Assembly: A Step-by-Step Guide to Building Products Efficiently

Building products from individual components can be a rewarding experience, whether you're assembling furniture, electronics, or intricate models. The key to a successful assembly lies in understanding the correct order of operations. This guide will walk you through the essential steps to ensure that you assemble your products efficiently and effectively.

The Importance of Order in Assembly

When it comes to assembling products, the sequence in which you put together the parts is crucial. Each component often relies on the previous one, and skipping steps can lead to complications or even failure of the final product. By following a systematic approach, you can avoid common pitfalls and achieve a polished result.

Gathering Your Tools and Materials

Before diving into the assembly process, it’s essential to gather all necessary tools and materials. This preparation phase can save you time and frustration later on. Here’s a checklist to help you get started:

- All parts and components

- Assembly instructions or manual

- Tools (screwdrivers, wrenches, etc.)

- Workspace (clean and organized)

Understanding the Assembly Instructions

Every assembly project comes with a set of instructions. Take the time to read through these guidelines thoroughly before beginning. Familiarize yourself with the parts and their functions. This understanding will help you visualize the final product and make the assembly process smoother.

Step-by-Step Assembly Process

Now that you have your tools and instructions ready, it’s time to start assembling. Follow these steps to ensure a successful build:

1. Lay Out the Parts

Start by laying out all the parts in an organized manner. Group similar components together and ensure that you can easily access each piece. This organization will streamline the assembly process and reduce the chances of losing small parts.

2. Begin with the Base

Most products have a foundational component that serves as the base. Begin your assembly by securing this part first. Ensure that it is stable and properly aligned, as this will support the rest of the structure.

3. Add Components in Sequence

Follow the instructions closely and add components in the specified order. Each piece should fit snugly into place. If you encounter resistance, double-check the alignment and ensure that you are using the correct part. Patience is key during this stage.

4. Secure Connections

As you add each component, make sure to secure connections properly. Use the appropriate tools to tighten screws, bolts, or any other fasteners. A well-secured assembly will enhance the durability and functionality of the final product.

5. Perform Quality Checks

After assembling each section, take a moment to perform quality checks. Ensure that all parts are correctly installed and that there are no loose connections. This proactive approach can prevent issues down the line.

Troubleshooting Common Assembly Issues

Even with careful planning, you may encounter challenges during the assembly process. Here are some common issues and how to resolve them:

Misaligned Parts

If parts do not align correctly, double-check the assembly order. Sometimes, reversing a step can help realign components. If the issue persists, consult the instructions for guidance.

Missing Components

In the event of missing parts, refer to the parts list in the instructions. If you find that something is indeed missing, contact the manufacturer for replacements. Do not attempt to proceed without all necessary components.

Loose Connections

Loose connections can compromise the integrity of your assembly. If you notice any instability, revisit the connections and tighten them as needed. Ensure that you are using the correct tools for the job.

Finalizing Your Assembly

Once you have completed the assembly, take a step back and admire your work. Conduct a final inspection to ensure everything is in place and functioning as intended. If applicable, test the product to confirm its performance.

Conclusion: The Satisfaction of a Job Well Done

Assembling products from small parts can be a fulfilling endeavor when approached with the right mindset and techniques. By following the correct order of operations and being mindful of potential issues, you can create a final product that meets your expectations. Embrace the process, and enjoy the satisfaction that comes from building something with your own hands.

Rate the App

User Reviews

Popular Apps

Editor's Choice