Latest Version

1.7

January 04, 2025

GAMINICS OYUN YAZILIM VE TICARET PAZARLAMA ANONIM SIRKETI

Games

iOS

273.8 MB

0

Free

Report a Problem

More About Gold Panning Shooter

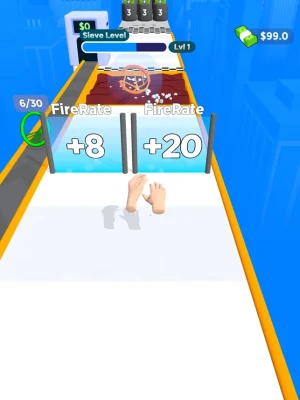

Enhance Your Metal Extraction with Robust Sieves

In the world of metal extraction, the quality of your tools can significantly impact your success. One of the most effective ways to improve your metal recovery process is by utilizing stronger sieves. By incorporating durable sieve pieces into your operations, you can maximize the extraction of valuable metals from muddy terrains. This article will explore the benefits of using robust sieves and provide insights on how to optimize your metal recovery efforts.

The Importance of Strong Sieves in Metal Extraction

When it comes to extracting metals from muddy areas, the strength and durability of your sieves play a crucial role. Traditional sieves may not withstand the rigors of heavy-duty use, leading to inefficiencies and potential losses in valuable materials. Stronger sieves are designed to endure harsh conditions, ensuring that you can effectively separate metals from debris without compromising the integrity of your equipment.

Benefits of Using Durable Sieve Pieces

Investing in stronger sieve pieces offers numerous advantages that can enhance your metal extraction process:

- Increased Efficiency: Robust sieves allow for faster processing times, enabling you to sift through larger volumes of material in a shorter period.

- Improved Recovery Rates: With enhanced durability, these sieves can capture more valuable metals, reducing the amount of material lost during extraction.

- Cost-Effectiveness: Although stronger sieves may require a higher initial investment, their longevity and efficiency can lead to significant cost savings over time.

- Versatility: Durable sieves can be used in various environments, making them suitable for different types of metal extraction projects.

How to Choose the Right Sieve for Your Needs

Selecting the appropriate sieve is essential for optimizing your metal extraction efforts. Here are some key factors to consider:

Material Composition

Look for sieves made from high-quality materials such as stainless steel or heavy-duty plastic. These materials offer superior strength and resistance to wear and tear, ensuring that your sieves can withstand the demands of metal extraction.

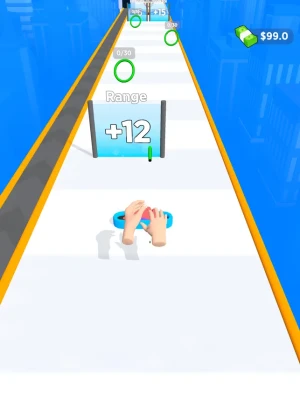

Mesh Size

The mesh size of your sieve will determine the size of the particles you can separate. Choose a mesh size that aligns with the types of metals you are targeting. A finer mesh may be necessary for smaller particles, while a coarser mesh can be effective for larger debris.

Design and Construction

Consider the design of the sieve, including its frame and support structure. A well-constructed sieve will provide stability and prevent deformation during use, ensuring consistent performance.

Best Practices for Using Sieves in Metal Extraction

To maximize the effectiveness of your sieves, follow these best practices:

Regular Maintenance

Keep your sieves clean and free from debris to maintain optimal performance. Regularly inspect for any signs of wear and replace damaged components as needed.

Proper Technique

Utilize the correct sifting technique to ensure thorough separation of materials. Avoid overloading the sieve, as this can lead to inefficient processing and potential damage.

Monitor Performance

Track the performance of your sieves by measuring recovery rates and processing times. This data can help you identify areas for improvement and make informed decisions about future investments in equipment.

Conclusion

In conclusion, the use of stronger sieves is a game-changer in the field of metal extraction. By investing in durable sieve pieces, you can enhance your efficiency, improve recovery rates, and ultimately increase your profitability. Remember to choose the right sieve based on material composition, mesh size, and design, and follow best practices to ensure optimal performance. With the right tools and techniques, you can successfully extract valuable metals from muddy areas and elevate your metal recovery operations to new heights.

Rate the App

User Reviews

Popular Apps

Editor's Choice